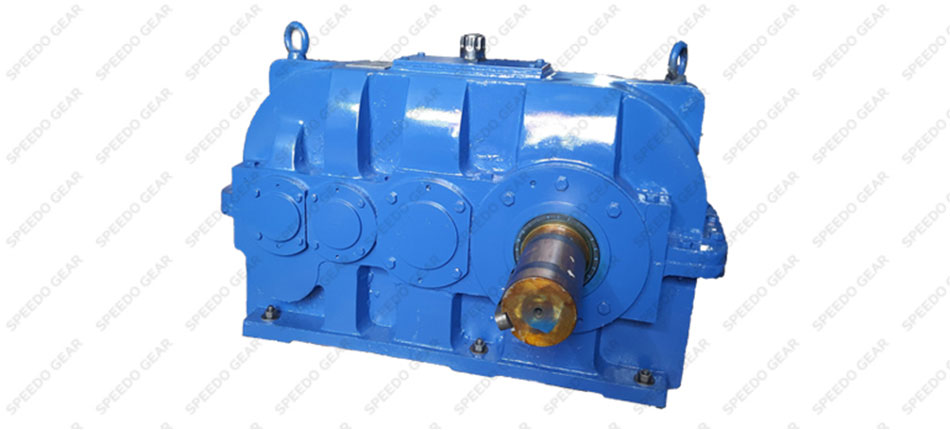

The high and low speed shafts must be in the same horizontal plane and parallel to one another for a parallel gear drive to exist.

For applications requiring a lot of horsepower and torque, parallel shaft gear boxes are typically chosen.

Speedo Gears One of the leading providers and manufacturers of parallel shaft helical gearboxes. We produce and provide a variety of gears and gearboxes tailored to your industries. We may create a parallel helical gearbox specifically for you to meet the needs and requirements of your applications.

Give us a description of your needs, and we’ll offer you practical advice on how to design a parallel shaft geared motor that will work in even the most difficult conditions. We are the preferred supplier of parallel shaft helical gearboxes for all of our clients in India and internationally since every gearbox that leaves our production facility is of the highest calibre.

We are here to offer all of our client’s complete gear solutions and services from anywhere in the world. We develop and produce high-performance F series helical geared motors to satisfy the needs of light, medium, and heavy-duty industries.

In order to employ extruder gearboxes in a wide range of applications that operate in the most difficult situations, are you looking for reliable manufacturers? Reach out to us right away, and we’ll go above and beyond to meet your deadline needs.

Product Specification

| Type | Helical (Multi stage) |

|---|---|

| Power | Higher power ratings for maximum torque from 5.5 Kw to 100 Kw and upto 10000 Nm |

| Ratios | Available in Single, Double, Triple and Quadruple stage in Ratios of up to 8:1 TO 100:1 |

| Housing | cast iron case construction. |

| Lubrication | Mineral gear box |

| Input | Solid Shaft with Keyway. |

| Output | solid Shaft with Keyway or Taper sleeve. |

| Input Speed | 1440 / 960 rpm |

| Orientation | Horizontal |

| Application | Cement, sugar, paper and pulp industry, plastic, ball mills, ribbon blender, power plants, EOT cranes. |