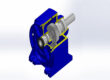

For small industrial machines under 5 kW—like pumps, conveyors, mixers, and fans—gear motors play a crucial role. Whether you choose a Three Phase Gear Motor, Electric Gear Motor, AC Geared Motor, or Worm Gear Motor, these drives combine efficiency, durability, and compact design to deliver reliable performance.

What Makes a Gear Motor Special

A gear motor integrates a motor with a gear system, ensuring torque multiplication and controlled speed. In low-power setups, especially with a three-phase supply, gear motors provide smoother torque, reduced vibration, and greater efficiency compared to single-phase options

Three Phase Gear Motor

Offers constant torque, high efficiency, and stable operation for industrial tasks.

Electric Gear Motor

A broad category covering AC and DC gear motors for various automation needs.

AC Geared Motor

Ideal for continuous-duty applications where precise speed control and reliability are essential.

Worm Gear Motor

Compact and highly effective for right-angle drives, providing high torque in limited spaces.

Advantages of Gear Motors at Low Power

- Superior Efficiency

A Three Phase Gear Motor typically achieves efficiencies of 85–90%, making it more cost-effective than single-phase drives. - Durability & Long Service Life

With fewer wear parts and sealed housings, Electric Gear Motors demand less maintenance and withstand harsh industrial conditions. - Lower Operational Costs

The initial investment pays off through reduced energy bills, simpler wiring, and fewer breakdowns.

- Smooth Performance

AC Geared Motors ensure steady torque with minimal noise, protecting machinery and enhancing product quality. - High Torque in Compact Frames

Worm Gear Motors deliver maximum torque in tight spaces, making them ideal for conveyors and packaging systems.

Where Gear Motors Excel Under 5 kW

- Booster and process pumps

- Small compressors and fans

- Light mixers and conveyors

- Auxiliary machine tool drives

Selection Tips Before Buying

-

- Choose the right gear motor type based on duty cycle and load profile.

- Use VFD-compatible gear motors if variable speed is needed.

- Ensure the right protection class for dust, moisture, or heat.

- Opt for high-efficiency gear motors where energy savings matter.

- Check for local spares and service support before finalizing.

FAQ (Frequently Asked Questions)

What is a gear motor?

A gear motor is an electric motor with a gearbox that reduces speed and increases torque for industrial use.

What is the difference between single-phase and three-phase gear motors?

Single-phase motors suit small loads, while three-phase motors are more efficient and reliable for heavy-duty operations.

What are the advantages of a three-phase gear motor?

They offer higher efficiency, smoother operation, better torque, and durability under continuous duty.

What is an AC geared motor?

It’s a motor powered by alternating current with a gearbox that provides high torque at reduced speed.

What is the difference between an electric gear motor and an AC geared motor?

Electric gear motor is a broad term (AC/DC), while AC geared motor specifically runs on alternating current.

What is a worm gear motor?

A worm gear motor uses a worm and wheel to deliver right-angle motion with high torque and compact design.

How do I choose the right gear motor?

Consider torque, speed, duty cycle, mounting type, environment, and power source.

How do I maintain gear motors?

Regular lubrication, sealing, proper alignment, and overload prevention ensure long service life.