There are 6 Types of Industrial Gearbox & Their uses

A closed system that transfers mechanical energy to an output device is called an industrial gearbox. Gearboxes can alter their speed, torque, and other characteristics to transform the energy into a usable form. Gearboxes serve a wide range of functions in a variety of devices. To improve torque and speed, these machines can reduce the rate of rotation. The following will describe some of the various industrial gearbox types and how they are typically used.

Helical GearBox

A helical gearbox is composed of a number of helical gears. A cylindrical gear with a slanted tooth trace is referred to as a helical gear. Compared to spur gears, they are quieter, have less vibration, and can move bigger loads. In spite of the fact that a set of helical gears has its helix hand on the opposite side, the helix angle is the same. Click here to read more about the helical gearbox.

In automotive transmission applications, spur gears are typically replaced by helical gears. In contrast to spur variations, helical gearboxes and helical gearboxes can run smoothly. The face of a helical gear determines the angle at which its teeth are cut. In other words, as the action progresses, the contact gradually forms at one location of the teeth and is maintained until the gear enters a state of full engagement. The most common type of gear used for transferring is helical, and it also generates a lot of thrust.

Inline Helical Gearbox SP – Series

Inline Helical gearbox is a rotating machine part having teeth or cogs that meshes with another toothed part to transmit torque. In layman’s terms, gears are one of the most crucial parts of every motor and machine that, by supplying gear reduction and changing the rotational direction, help to increase the torque production. A group of two or more gears working together is referred to as a transmission or SP Series helical gearbox. Geared devices are more likely to alter the speed, torque, and direction of a power source.

Industrial gearboxes have a wide range of specific applications and are utilised in both small and large-scale organisations. There aren’t many top industrial gearbox builders in the entire world. They specialise in the production of worm, helical, planetary, and gear motor gearboxes for industrial applications. We will discuss the working, efficiency, and applications of the helical gearbox in more detail in this post.

M – Series Helical Gearbox

Helical Gearbox M Series in three stages for big loads and higher service factors. High-grade materials were used in the die casting of this gearbox. The items are put through a number of quality checks in accordance with established industrial grades. All gear is produced using case-hardened alloy steel and is machined with greater accuracy on CNC machines for reduced noise and increased productivity. For applications requiring low RPM and heavy loads, the M series is a three stage gear mechanism.

Axial thrust loads are provided by helical gears while they are not with spur gears due to the twist in the tooth trace. Therefore, it is appropriate to use thrust bearings to handle this tension. By combining left- and right-hand helical gears, it is possible to build double-helical gears and eliminate the thrust force.

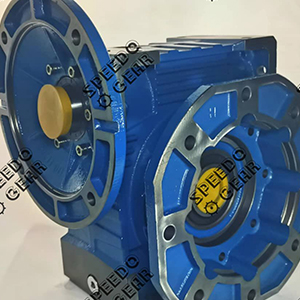

NMRV Worm Gearbox

The NMRV Worm Gearbox was successful and received positive feedback from our devoted customers. With our extensive experience, we are able to provide our customers with an excellent selection of Aluminium Worm Gear boxes at fair pricing. These are mostly used in a variety of heavy industries across numerous sectors. To guarantee noise level and oil leakage, these worm gear boxes are constructed and tested in accordance with predetermined industry standards. Boxes 30 to 90 will have aluminium bodies, while Boxes 110, 130, and 150 will have casting bodies.

We produce lightweight NMRV worm gear boxes with aluminium bodies for the engineering sector, specifically for manufacturers of packaging equipment with different centre distances. While producing and marketing a high-quality selection of Worm Speed Gearboxes, we bear in mind the unique needs of our clients.

Parallel Shaft Helical Gearbox

Helical gearboxes with parallel shafts. We create and supply a variety of gears and gearboxes that are specially designed for your industry. For your unique demands and application specifications, we might design a parallel helical gearbox just for you. We can develop a parallel shaft geared motor that will function in even the most challenging circumstances if you describe your needs to us. Contact us for more information. Since every gearbox that leaves our production facility is of the finest calibre, we are the preferred provider of parallel shaft helical gearboxes for all of our clients in India and beyond.

A parallel gear drive can only exist if the high and low speed shafts are in the same horizontal plane and parallel to one another. Parallel shaft gear boxes are frequently used in industrial applications that demand high horsepower and torque.

Worm Reduction Gearbox

Heavy duty operations are driven by worm reduction gearboxes. Worm gearboxes are employed when more speed reduction is required between crossing axis shafts that are not intersecting. This kind of industrial gearbox makes use of a large-diameter worm wheel. The teeth on the outside of the gearbox are where the worm, or screw, meshes with them. The wheel moves similarly to the worm’s rotational motion because of the screw-like action. The majority of these industrial gearboxes are employed in large industries including minerals, chemicals, and fertilisers.

As a result, you can use it to either boost torque or significantly decrease speed. Worm gear users have fewer moving parts and fewer points of failure because it often takes several reductions of a traditional gearset to attain the same reduction level as a single worm gear.